Crossing signals serve a vital function in traffic management, public safety, and railway operations–through auditory, tactile, and visual means, they alert road traffic to the presence of a train, and for good reasons–at mainline speeds, it takes over a mile to stop a sizable freight train safely, and the collision between a train and an automobile has been compared to an automobile hitting a soda can.

This blog will mostly focus on “active” signals built after 1936, which is to say signals with lights, bells, and/or gates. However, in so doing it will also delve into more historic examples, as well as blurbs on different types of “passive” signals.

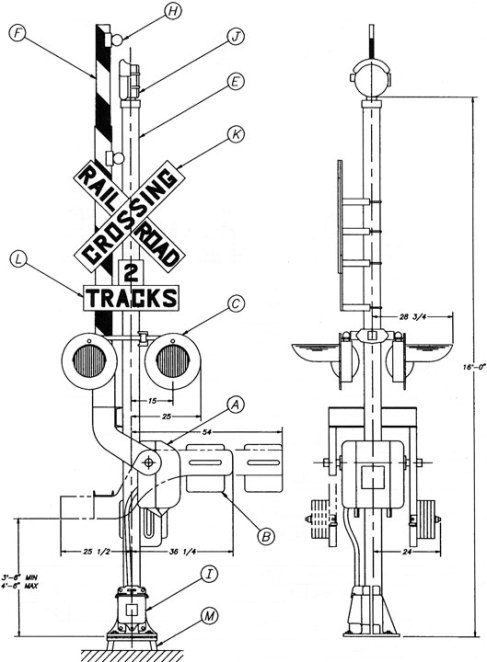

For this basic description, we’re going to look at the most commonplace gated signal, the Western-Cullen Hayes “Model 10”. First offered in 1936, it has served as the basis of the “modern” crossing signal offered by US&S, Safetran, and several other builders.

Let’s start with the most important part of the signal–the gate mechanism, arm, and gate itself. This portion of the signal blockades the roadway when a train gets within a certain distance of the crossing.

[Photo by Google: A-Frame Crossing Gate in San Diego, CA]

Up until the 1950s, crossing gates were made of wood, arranged in an “A-Frame” design with structural reinforcement. This type of crossing gate was common on manually-operated crossings from the 19th Century.

[Personal Collection – a Model 10 at Lost Winds Beach, San Clemente, CA]

More recent crossing signals use a rectangular gate constructed either from fiberglass or metal, sold in prefabricated lengths or in an adjustable kit. While they are much lighter than A-Frame gates and thus exert less of a strain on the gate mechanisms, they also are much more fragile. The gate is attached to the motor by the gate arm by a shear-pin to prevent damage to the gate itself in the event of high winds or a vehicle striking the gate.

[Personal Collection: Relay Lights on BNSF’s crossing display at Fullerton Railroad Days]

Also attached to the gate are “relay” lights. These serve the same function as flasher units, and help make the gate visible under inclement lighting conditions.

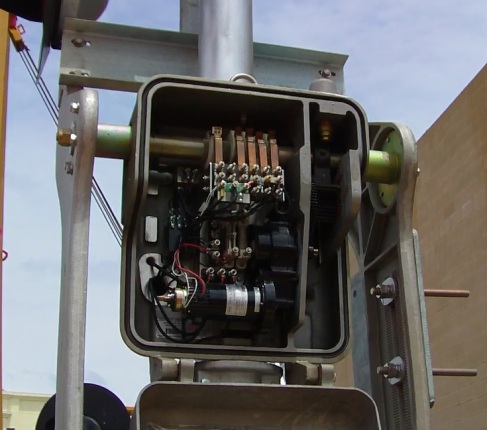

[Personal Collection: US&S Model 95 Gate Mechanism on display at Fullerton Railroad Days]

The gate mechanism contains a low-torque motor and its affiliated circuitry, as well as a set of reduction gears. Also inside the mechanism housing is the “hold-clear” system, which keeps the gate up while inactive.

[Personal Collection: An octet of Western-Cullen Hayes flashers with 1st-generation LEDs protects a pedestrian crossing from an oncoming Amtrak in Carlsbad, CA]

Further up the mast are the flashers. Initially designed by the Griswold Signal Company in the 1920s, these are red flashing lights surrounded by black backgrounds and visors to improve daytime visibility. Aside from a few minor changes since, the overall concept has remained the same–a pair of these flashers facing a single direction, each one alternating between being on and off (colloquially known as “wigwagging”), and with as many pairs as needed to ensure the signal’s visibility. Most road signals have two pairs, projecting their light roughly parallel to the roadway. However, crossings will have more than two pairs of flashers, especially if visibility is an issue.

[Personal Collection: A “Type D” style crossbuck and “2 Tracks” sign in Carlsbad, CA]

Further up the mast are the road signs–the “Crossbuck” and the “Track Signs”, if more than one track is crossed. These typically inform motorists of the location of a grade crossing as well as the number of tracks at the crossing. A detailed collection of crossbuck vectors by the late Michael J. Hickok is availiable here.

The last major warning device on a modern grade crossing is the bell. Through a means of mechanically striking a gong (or simulating the sound electronically) crossing bells provide an audible warning for motorists and pedestrians alike. The first technical crossing bell is an oft-disputed topic, but it boils down to two separate builders–Bryant Zinc Company (purchased by WRRS / Western-Cullen Hayes) creating the first technical Mechanical Bell in 1909, or Union Switch & Signal creating the first formal railroad crossing bell–nicknamed the “Teardrop Bell” due to its peaked rainshield–in 1917.

However, both major crossing signal companies–Western-Cullen Hayes and Safetran–and their predecessors each created a distinctive style of Mechanical Bell from the 1920s up until today. In fact, a Western-Cullen Hayes mechanical bell retails for $250.

[Personal Collection: One of the last WRRS Mechanical Bells on the Surf Line does what it does best in San Juan Capistrano, CA]

The Western-Cullen Hayes style of mechanical bell is derived from the Bryant Zinc mechanical bell of 1909, featuring a 12-inch gong and a thin rainshield protecting the contact point. Western Railroad Signal [WRRS], Federal Signals, Modern Industries, and later Westinghouse and US&S all produced derivations of this design. The most common variant of this bell is the Western-Cullen Hayes 0333 mechanical bell, purchased en masse by many railroads all over the globe, noted for their reliability.

[Personal Collection: A RACo Mechanical bell on an ex-ATSF signal in Irvine Regional Park]

The other type of mechanical bell common on North American crossing signals was first built by the Griswold Signal Company in 1920, for use on their rotating banner signals. Another Minneapolis-based firm, RACo, also produced a similar design of mechanical bell, and the design continued to be built long after Griswold was absorbed by Safetran, now Invensys Rail.

[Personal Collection: Safetran “Type 2” Electronic Bell in San Clemente, CA]

Due to maintenance issues and their sheer weight, mechanical bells fell out of favor in the mid-2000s, when the first viable Electronic Bells entered the market through General Signals and Safetran. Designed to simulate the sound of a mechanical bell through a speaker system, electronic bells were easier to install, cheaper to build, and could operate with less maintenance. Electronic bells became loved amongst railroad staff for their reliability and ease of installation, and reviled by signal fans for not sounding quite like their beloved mechanical bells.

However, this guide barely scratches the surface of the multitude of unique crossing setups. Depending on the circumstances, crossings can be equipped with cantilevered flashers for low-visibilty locations or “quad-gates” for larger, busier roadways. As such, each grade crossing–no matter how generic it is on the factory floor–takes on a unique role in traffic management and public safety, all to warn people of an oncoming train.